-

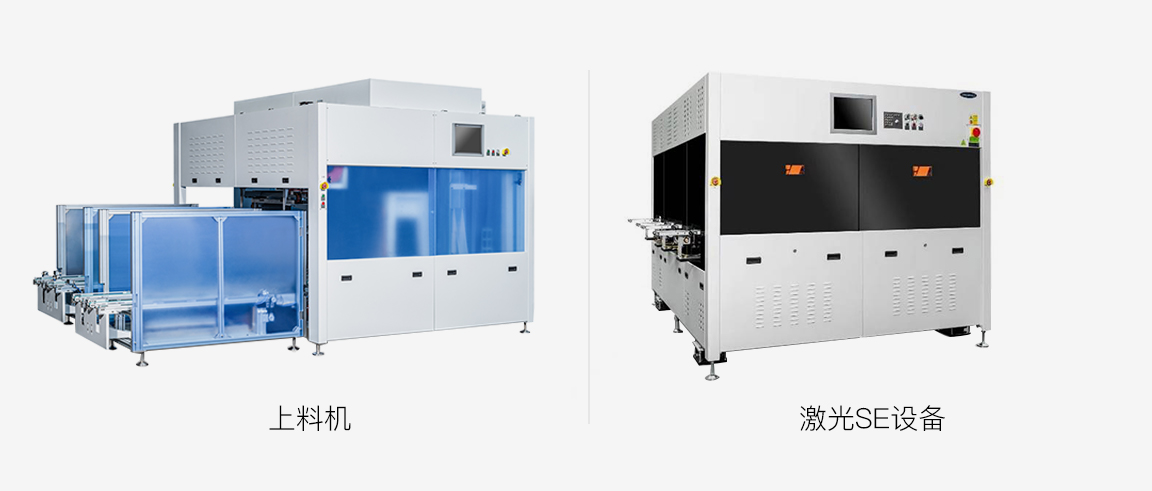

1. Equipment Size : 5000mm x 2500mm x 2260mm

-

2. Silicon Wafer Size : 156mm x 156mm ~ 230mm x 230mm , Thickness : 140~220μm

-

3. Four-head Productivity : M10≥9500PCS/H ; M12 ≥8000PCS/H(Compatible with 230mm wafer , higher production capacity of four laser heads optional)

-

4. Breakage Rate ≤ 0.05%(Except for cracks of incoming materials)

-

5. Uptime ≥ 95%

-

6. Laser Wavelength : 532nm

-

7. Laser Frequency > 500Khz

-

8. Laser Power : 25w~60W

-

9. Power Stability < 2% RMS

-

10. Laser Lifetime ≥ 50000小时

-

11. Scan Mode : Galvanometer Scanning

-

12. Spot Size : 90 ~ 130um(Round/square optional; size optional)

-

13. Scanning Speed ≥ 50m/s

-

14. Graphic Marking Accuracy ≤±15μm(incoming material)

-

15. Loading Breakage Detection : 12 million pixels (general) , Edge collapse and corner missing detectable

-

16. Graphics Compatibility : Compatible with plt, dxf, dwg graphics formats(Compatible with points, lines and segments)

-

17. Dust Removal and Filtration Efficiency : Dust removal eff. ≥95%; filtration eff. ≥99%(Independent dust removal equipment, exhaust air volume up to 2000m3/h)

-

18.

-

19.

-

20.

-

21.

-

22.

-

23.

-

24.

-

25.

-

26.

-

27.

-

28.

-

29.

-

30.