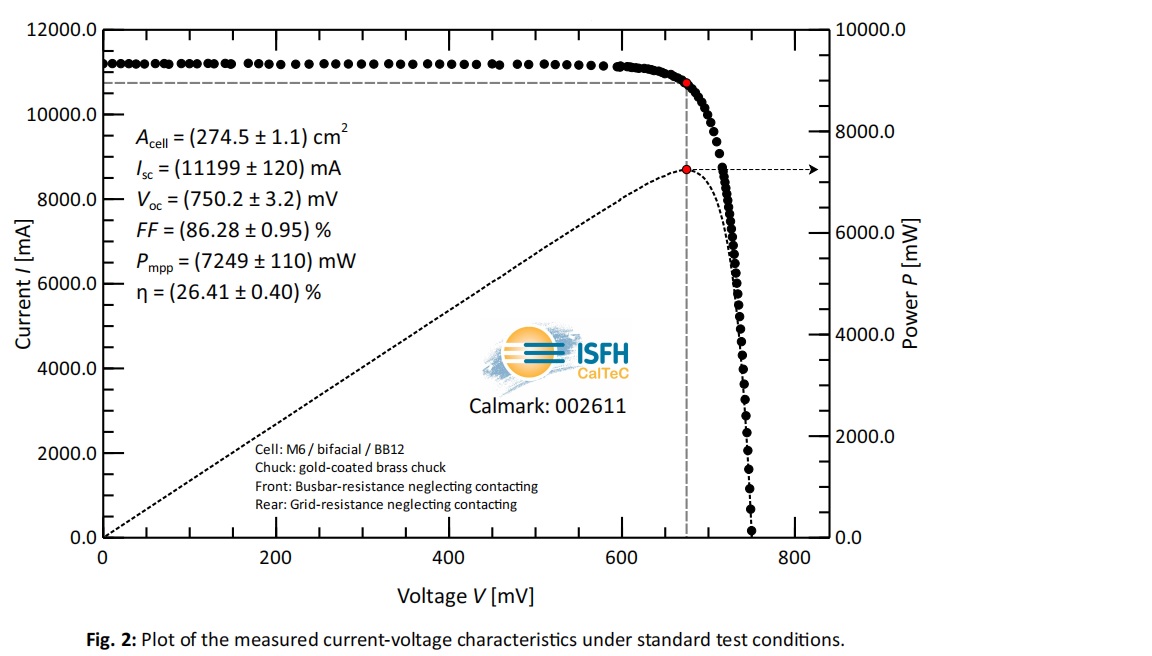

Certified by the Institute for Solar Energy Research (ISFH) in Germany, Maxwell has achieved a photoelectric conversion efficiency of 26.41% on full size (M6, 274.5cm²) N-type crystalline silicon HJT cell which adopted its self-developed microcrystalline equipment technology combined with copper plating busbars of SunDrive.

The cell efficiency is 0.34% higher than the 26.07% that the two companies announced in March this year, and the short-circuit current (Isc), open-circuit voltage (Voc) and fill factor (FF) of the certified cells are all improved. The PECVD process for this batch of cells was completed on the latest generation of Maxwell’s mass-produced double-sided microcrystalline equipment, with optimized passivation layer and microcrystalline P process, meanwhile combined with new TCO process of PVD. For the metallization of cell , SunDrive optimized the direct plating technology without seed layer, improving the aspect ratio of the electrode (the width and height of busbars reached 9 μm and 7 μm respectively).

Maxwell and SunDrive have cooperated since 2021 to develop high-efficiency HJT cells. Maxwell provides all processes of blue wafer (including Texturing, PECVD and PVD, etc.), which are completed on the mass production equipment of HJT cells developed by Maxwell. The electrode of cell is made by SunDrive with its seedless direct copper plating equipment. Through technical iteration and process optimization in less than one year, the conversion efficiency of the silver-free HJT cell jointly developed by the two companies has been repeatedly certified by ISFH, rapidly rising from 25.54% to 26.41%.

In the future, Maxwell will continue to focus on the R&D innovation of HJT technology, and promote the development of mass-production applications of HJT through more advanced equipment and improved technical solutions.